Iran Ferrosilice CO's Comprehensive Environmental Plan

In the company’s overarching plan, environmental improvement measures are designed, planned, and executed through using online, real-time environmental monitoring sensors. By sampling and modeling the acquired data, this initiative aims to assess distribution patterns in the region, scrutinize the impacts of pollutant sources, and enhance environmental monitoring. Modeling stands out as a crucial tool in these efforts, aiding in accurate calculations and informed decision-making.

Solutions to Prevent Air Pollution

Establishing ISO 14001:2015 environmental management system

To protect the environment and prevent its pollution throughout the product life cycle, organize the work environment and avoid its pollution, reduce the consumption and preserve natural resources and consequently reduce costs, safety, and health, recycling and waste management, create Better communication with legal institutions and compliance with environmental regulations and laws, sustainable development and proof of the organization’s commitment to the social responsibility of the ISO 14001 standard, which this company has developed since ???.

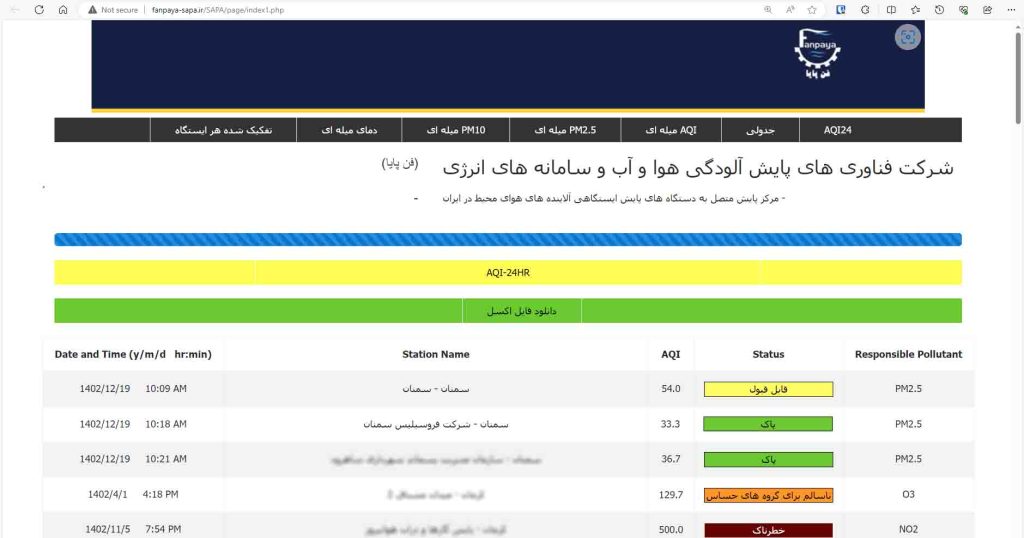

Carrying out environmental monitoring in the form of a self-declaration plan and registration in the environmental system.

Based on paragraph A of Article 61 of the 4th Development Plan, Iran Ferrosilice has implemented a self-declaration plan in pollution monitoring.

Installation of online and real-time monitoring on the outlet of the dust collector and the main chimneys of the smelting unit.

Based on Article 192 of the Law of the Fifth Program of the Development of Pollutants Control System, it has been installed and operated in the Iran Ferrosilice factory since 1999. The measurement process has been significantly improved with the installation of a new system since 2013, and the storage of information on the server is continuous and online. It can be viewed and reported.

Cooperate with scientific centers to control environmental indicators and submit continuous reports to the General Department of Environment.

Enclosing the charging funnel of carbon materials.

Construction of a dust storage shed and optimization of the dust collection system.

Installation of dust collection system on the crushing and granulation line of Ferrosilicon Magnesium product, casting lines, charging system.

Installation of 75 and 90 kW spare fans in the dust hall to prevent emergency situations.

Development of Green Spaces and Collaboration with Natural Resources and Watershed Management Organization in Tree Planting Efforts

Recognizing the pivotal role of vegetation in mitigating air pollution, Iran Ferrosilice Company has undertaken initiatives to expand its green spaces in recent years while adhering to the crucial principle of water conservation. This has involved the implementation of drip irrigation systems.

Planting 1,000 pine, olive, eucalyptus, and rosemary trees within the factory premises.

Removal of charcoal and wood chips from production raw materials.

Material Management and Waste Control

Iran Ferrosilice is committed to ensuring a healthy environment for its employees and neighboring communities. Through the implementation of its comprehensive environmental plan, the company has effectively managed dust emissions within the workshop environment. This proactive approach not only fosters a healthy atmosphere within the facility but also ensures minimal impact on the surrounding environment.

It’s worth noting that the type of dust produced in our factory differs significantly from silica particles emitted by other industrial activities such as stone-quarrying, sand-casting, and sandblasting units. Unlike Silica Dust, which is associated with respiratory diseases, the dust generated in our operations does not pose such health risks. We’re pleased to report that our workforce has not shown any signs of respiratory issues attributable to our operations. Consequently, our activities do not pose any health concerns for the residents of Semnan city.

Driven by its environmental commitment, Iran Ferrosilice employs cutting-edge dust removal systems, enabling the company to address the demands of various industries such as concrete, construction, refractories, and polymers. Through meticulous management and using advanced technologies, we produce 8 to 10 thousand tons of Microsilica powder annually while integrating dust back into the production cycle.

Development and implementation of material management and waste control guidelines in accordance with ISO 14001 standards

Conducting environmental risk assessments for processes and implementing control measures for identified risks

Waste management practices including collection, transportation, processing, and disposal in alignment with environmental principles and public health standards

Using high-quality raw materials and recycling production waste to fulfill material management objectives

Adoption of updated technologies and software for internal and external communication to reduce paper consumption

Minimization of disposable materials and products to mitigate environmental impact

Segregation of organic and inorganic waste to enhance recycling management efforts

Production of high-quality products to reduce production waste

Efforts in Social Responsibility

Allocation of over half a billion tomans annually, sanctioned by the esteemed board of directors, towards national duty, humanitarian, and charitable endeavors in Semnan city. This budget is used for constructing and equipping hospitals, schools, aiding the needy, supporting charitable institutions, and promoting sports.

Procurement of equipment for the proscopic department at Kosar Semnan Hospital.

Provision of an echocardiography device and an ultrasound device to Kausar Semnan Hospital, facilitated by the dedicated efforts of Mr. Majid Mohammadzadeh, a major shareholder and one of the founders of Iran Ferrosilice CO.

Donatation to Golhaye Behesht Rehabilitation and Care Center for the Mentally Disabled

Financial assistance extended to the Iran Thalassemia Society, and Kahrizak Charity

Support for the fund-raising ceremony aiding in prisoner release

Efforts in job creation including self-employment and home-based jobs

Backing the poor and deprived members of society

Provision of grants to company personnel in various circumstances, including illness

Assistance in the implementation of the water supply project to Semnan industrial town

Financial support for the Imam Khomeini Relief Foundation of Semnan.

Participation in the construction of a school named after the Great Prophet (PBUH)

Iran Ferrosilice Company (public shares) demonstrates its commitment to social and cultural responsibility through its involvement in constructing and operating of the Great Prophet School in Semnan. This initiative, undertaken in 2018, encompassed establishing 12 classrooms spanning an area of 2098 square meters on a land plot measuring 4270 square meters. This endeavor represents a modest yet significant step towards enhancing the educational landscape and scientific standards within the province.

Collaboration with universities to facilitate student internships

Financial Aid for athletes and sports teams to promote sports culture and vitality in society

- Sponsorship for the women’s karate team for participation in international competitions

- Sponsorship for the Semnan kabaddi team

- Financial Aid to the Semnan Volleyball Association

- Provision of uniforms for the Semnan youth basketball team

- Provision of uniforms for the Semnan Part football team